The push-pull design for output stages has persisted since times of antiquity. It was one of the very earliest circuit designs, and has persisted until the present day, with modern solid-state linear amplifiers still overwhelmingly using it.

With tubes, a typical topology is given by the circuit below. (Click to magnify). The anode (plate) voltage on either side comes through the primary of the output transformer.

This design uses a pentode tube, which has a screen grid. This is attached to taps on the output transformer to run in Ultra-Linear mode, increasing efficiency and reducing distortion.

In this design, the cathodes are tied to ground through a very low value shunt resistor. The resistor is simply there to provide a small voltage drop from which the current through the tube can be measured. It plays no other role in the circuit, other than being a fuse if the tube red-plates.

Values of one ohm or ten ohms are typical of this arrangement.

Because the cathode is at (or very close to) ground potential, this requires the control grid to have a negative DC bias voltage applied to it, to regulate the flow of current through the tube.

If there was no negative bias applied to the tube, it would go into full conduction, the plate would glow red hot, fireworks will happen and that would be Bad, mmkay?

So we need to contrive to feed a constant negative voltage into the grid, along with the signal, to achieve the desired regulation.

The voltage required depends on several factors… as a very rough rule-of-thumb, take the screen voltage and divide it by the tube’s mu (gain) to get the maximum negative bias voltage likely to be needed

Looking at the circuit above… An EL84 has a mu of 20 and in this implementation the screen voltage is 350 (in Ultra linear we take the screen voltage as the same as the anode/plate voltage), which gives us 17.5 volts. Multiply by -1 since we’re dealing with negative volts. So we’re likely to need around -17.5 volts.In this case, our adjustment range is from -12.5 to -21.5 volts.

How to set up the bias adjustment resistor values

The bias voltage needs to be adjustable. Both tubes need to be drawing the same current, otherwise the net current through the transformer will not be zero, which will lead to magnetisation of the transformer core. This is a most undesirable situation and left unchecked, it will cause quantum fluctuations in the space-time continuum. Well ok maybe not that bad, but the transformer will saturate unevenly and distort the sound.

The usual approach is to use a voltage divider network with a potentiometer, as above.

Couple of points about this design.

- The more negative the voltage goes, the lower the current through the tube

- In this implementation, if the potentiometer fails, it will fail safe. The most common mode of failure with potentiometers is the wiper lifting off the track. If this happens, effectively the voltage at the grid of the tube will go full negative, reducing the current through the tube to (almost) zero. This is far more desirable than the voltage reaching zero and the tube immediately red-plating.

- Expanding on (2) – please don’t ever build this circuit with just the pot wiper connected to the grid. When the pot fails (and it will, eventually) it’ll likely take the tube with it.

- If you’re going to build this circuit, it’s intuitive to set it up so that clockwise rotation of the pot increases the current through the tube (ie brings the biasing voltage closer to zero)

The next question is – what value resistors will be needed? This is where some trial and error in the calculations is needed. Using Ohms’ law, these are the variables:

- The desired bias voltage adjustment range

- The input negative voltage from the power supply

From there, you can calculate the values for the resistors and potentiometer to give you the range you need.

This is where a spreadsheet can be mighty useful.

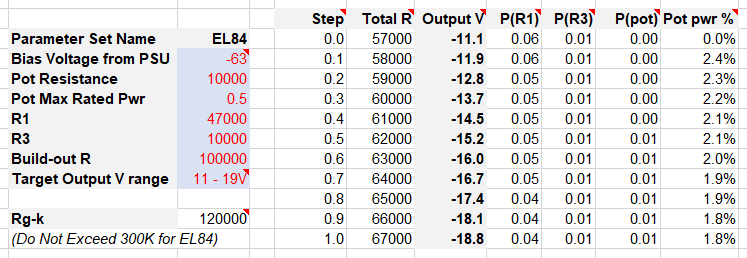

This is a screenshot from a spreadsheet I made that can help with this calculation. You can download this Excel worksheet here.

Put in the numbers in the red. Experiment with the values for R1 and R3 and the potentiometer, until you get the desired voltage range in the “Output V” column.

The “Build-Out R” represents the load seen by the preceding driver or phase-splitter stage, so watch the maximum “Rg-k” from the tube’s datasheet isn’t exceeded. In the case of an EL84, that value is 300K. (In the datasheet there will be a specification for this, and it’s diffrent depending on the mode of use of the tube. So look for the “two tubes, class AB” which is in most pentode/tetrode datasheets)

The columns of this spreadsheet:

- Step – the setting on the potentiometer

- Total R – the total resistance from the bias voltage to ground

- Output V – the negative voltage as fed to the control grid

- P(R1) – the amount of power dissipated by R1

- P(R3) – power dissipated by R3

- P(Pot) – the power dissipated by the potentiometer

- Pot pwr % – the power dissipated by the pot expressed as a percentage of the pot’s total power rating AND the amount of track being used to conduct.

About Pot pwr %

In the specifications for the potentiometer, there will be a power rating. However that power rating is across the entire length of the track. If the pot is set to half-position (assuming it’s a linear taper which in this design it is) then the power handling drops to half. So, this Pot pwr % column shows how much power the pot is dissipating as a percentage of its maximum taking the wiper position into consideration.

Using the circuit

Putting all this together, it’s easy to see how it works. Adjust the potentiometer for maximum negative voltage (wiper closest to the left, in this schematic). Power on the circuit and let it stabilize. Measure the voltage across the cathode resistor. Then adjust the potentiometer until the desired current is flowing through the tube.

What is the desired current through the tube?

Glad you asked. This depends on the tube itself, and the B+ voltage, and your preference regarding bias.

As a rule of thumb, biasing at around 70% of maximum is the sweet spot with most types when using this conifguration. If you bias low, that’s called “cold” biasing. It means the current through the tube will be low, and the sound may take on a thin, glassy, brittle aesthetic, and the distortion will increase. Bias too hot and you’ll shorten the life of the tubes for no real benefit. 70% is the goldilocks zone.

So. Look at the tube’s datasheet. For an EL84 we see the maximum plate dissipation is 12 watts.

- 70% of 12 watts is 8.4 watts

- B+ is 350 Volts

- So, using Ohms Law:

we solve for I at 24mA

Across 10 ohms (cathode resistor) our 24mA will give 0.24V

So we want to see 0.24V across the cathode resistor. Adjust the potentiometer until that’s the value shown. Then repeat for the other tube in the circuit, then do a final check that they’re both the same (or as close as you can get)

Please feel free to use my spreadsheet – I developed it to assist in choosing the resistor network values, and also to ensure the power rating of the potentiometer wasn’t being inadvertently exceeded at any setting.

Very halpfull, thanks for your job.

But why 10 Ohm resistor on 0,24V is as big as 1W power?

1W is not strictly necessary; 0.25W could be used. The resistor plays an important role as a fuse in the event of a bias failure. In that case, the tube would conduct as much power as the PSU could throw at it, red-plating in the process. In this case the 10R resistor could be expected to overheat and eventually fail.

Thank you so much for this…..exactly what I was looking for !

Cool – glad it helped you. After having built EL84 amps using both Fixed and Cathode bias, I’m convinced that fixed bias is the way to get the absolute maximum performance out of them. So long as you don’t mind the extra components needed.

I have an old 1973 Traynor combo guitar amp that is using 410V for the 2x EL84 B+. This is a design mistake I know but it would be nice if your Excel sheet allowed different B+ supplies even if bogus b/c abuse of the EL84 was somewhat common early on. .?

Hi – if you look at the section on the page “What is the desired current through the tube?” then you can put different values in as required. for 410 volts, assuming you are aiming for a plate dissipation of around 9W, then I = P/V so I = 9/410 or in other words around 22mA.

As a rough rule-of-thumb, take the screen voltage and divide it by the tube’s mu to get the approximate neg voltage needed. You haven’t said whether your amp is ultralinear (unlikely) or pentode (likely) and I don’t have a schematic for that amp, so you’d need to work out what your screen voltage might be. But, assuming it’s also 410 volts, the u for an EL84 is 19 according to the datasheet, so you’re likely to want about -22 volts on the control grid. So set your desired voltage range on the spreadsheet from -25 to -15 and that should get you into the approximate range you need.

Good luck!