Deep Space 845se55 July 2008

Last

edited November 2016.

Some minor comments have been clarified.

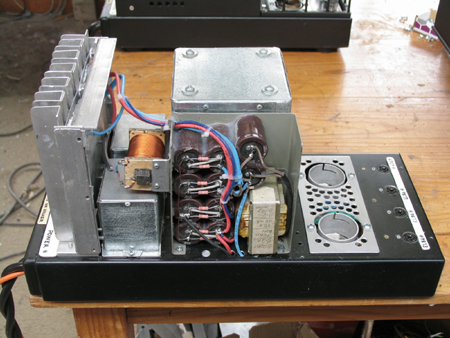

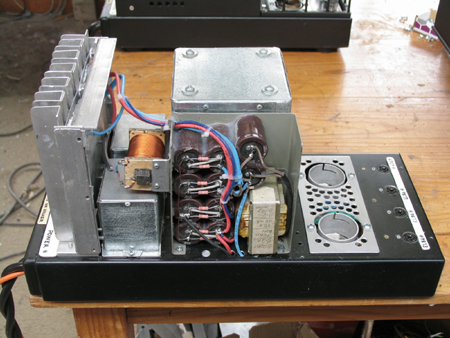

Photo 1, The two 55W amps on my bench.

After a few months of research and development, I completed

construction of a pair of 55W

class A1 monoblocs each using a pair of paralleled 845 triodes for

single ended operation.

These amps were a very difficult handcrafting challenge. I'd like

to think my discerning customer

who waited months will never find any better sounding amplifiers

with such natural clarity

and fidelity. During tests one evening a friend and I were reduced

to tears with some good

recordings. Only the best audio gear achieves a real emotional

impact similar to well performed

live unamplified music which has always been my “gold standard”

for audio quality.

The amps also have excellent technical performance with wide

bandwidth, low distortion,

low noise, and excellent damping factor.

Photo 2.

The first prototype monobloc had all the power supply components

and audio amp

components on the one chassis. But total chassis weight reached

42Kg, and it became

too difficult to move easily, and parts had to be crammed together

too tightly to allow

low chassis temperatures.

So I adopted the same principles I used in my 300W monobloc amps

to have two chassis

per mono channel with power supply on one and audio circuit on the

other, with each

chassis connected with very heavy duty umbilical cabling. This

reduced weight problems

and I could have all hot running resistors clamped inside a

heatsink on one end of the

chassis top instead of having them air cooled under-chassis, thus

the amps stay cool

even on hot summer days. Access to all encased resistors is

possible by unscrewing

the heatsink outer fins.

Each audio amp chassis weighs approximately 30Kg and is 520mm deep

x 230mm wide

x 280mm high.

Each power supply chassis weighs 16Kg and is 280mm deep x 200mm

wide x 250mm high.

Total amplifier weight for two channels is about 92Kg.

Rectifiers are all silicon, and the power supplies always run cool

and can be placed on the floor.

The audio amp chassis can be placed on a bench or equipment stand

above the power

supplies so the front on/off switch can easily be reached, and you

can keep an eye on the tubes.

Photo 3.

This shows a close up view with 1 x NOS AWV 6CG7 input,3 x Sovtek

EL84 triode drivers,

and 2 x KR Audio 845 output tubes.

Initial tests were done using "expendable" Chinese made 845

Shuguang type B which sounded

well and measured during many tests.

The amps are made to work with any brand of 845, but the Vac for

cathodes must be changed at

taps on power transformer windings must be changed to suit

Shuguang 845 which require 3.3A

x 10V while KR Audio only need 1A x 10V.

Thus KR tubes run cooler than the Chinese types. The same anode

voltage and anode current

at idle is used, ie, idle Pda = 73W for each 845.

The KR845 may possibly have a very slightly more detailed sound

than the cheapest type B

Shuguang Chinese 845, which I think is the best Chinese 845.

Neither my customer or myself

could hear any difference between KR or Shuguang. The KR tubes

certainly look better made

than the Chinese 845 which are a very close copy of the original

RCA 845 and other old ancient

brands. I did have a customer who bought a quad of Shanling 845

for his Ming Da amps, see

Ming-Da-PP-845-reformed.html

All 4 Shanling malfunctioned with arcing over internally with Ea

more than 500Vdc. The owner

could never get a refund for these overpriced and poorly made 845.

But he has has Shuguang

now for thousands of happy hours.

Both Shuguang and KR 845 had very similarly low distortion levels,

and both adjusted themselves

in my auto biasing circuit with the same biasing Vdc and bias Idc.

Both gave the same power

outputs with the same circuit.

The PSU for each channel produces two 10Vdc supplied for each 845

cathode with choke input

type filters, L + C, and there are 3 taps on two 13Vac windings on

PT so the cathode Vdc

can be finely adjusted for the correct level by choice of taps.

The highest current ever likely for

any 845 is 3.3A for the highest Vac tap is used. The KR may use

the lowest voltage tap for the

lower Idc at cathodes.

RCA or other brands of NOS are so rare now that it’s pointless

trying to find any. Because the

KR tubes use 20W less to heat their cathodes, they could be idled

at Pda = 100W. But the KR 845

are more than 3 times the price of the Chinese types so I have set

up the KR to run at about 75W

at idle to ensure long tube life. See the notes about the

operating conditions below.

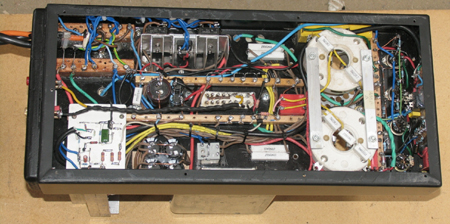

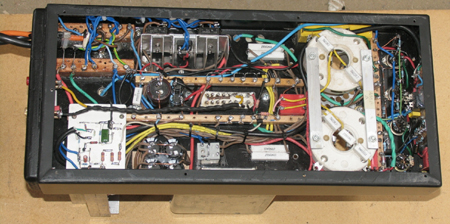

Photo 4.

The amp has its top cover removed in my workshop. You can see the

hand made heatsink to

the left which encloses all the main hot running resistors. Moving

right, the bar cored choke

aka solenoid is for CLC filter for the dc power applied to all

input and driver tubes. Under the

solenoid are two potted E&I chokes for the two choke input dc

cathode heating in each 845.

In the center towards rear is a large potted output transformer

with 72mm stack of 51mm

GOSS E&I lams.

At center front I have an Al channel with some of the 470uF filter

caps in main anode supply

rails and a 60H choke for 36mA dc anode supply to the 3 x EL84

triodes working in parallel.

The 845 'Johnson' tube sockets are recessed to reduce amp height.

4 McMurdo 9 pin sockets are at left end for smaller tubes. White

labels with black lettering

is used to indicate tube type & position to avoid people

swearing and cursing because they

cannot read tiny lettering in the gloom of a listening room.

Photo 5.

"Beneath the bonnet"of each audio amp chassis, top left, you can

see the entry and

terminations of the incoming umbilical cables. Towards the right

is a heatsink for three

diode bridges for dc heater supplies, then rail discharge

resistances, then underside of

Johnson tube sockets, and far right you see the compact wiring of

the 4 tube sockets for

input and driver stages. At bottom left is the active protection

board to shut down the amp

if an output tube draws excessive anode current, ie, malfunctions.

Towards the right there

is 60,000 uF in four caps for 845 heater filtering, then rail

discharge resistances.

All wiring is genuine point to point wiring with mainly hardwood

terminal strips well sealed

with varnish. Hookup wire has 1mm thick PVC insulation and is

multi strand copper chosen

for very long term reliability and with very generous current

ratings and much with an

additional shrink wrap layer of insulation added where voltages in

wires are over plus or

minus 600Vdc relative to 0V.

Right in the middle are two rows of terminals which allow a tech

to reconfigure the output

transformer secondary to suit loudspeakers of either 3-6 ohms or

6-or-more-ohms.

Speakers above 6 ohms may be used with the terminations set for

3-6, given excellent

fidelity but reduced power ceiling. 95% of listeners would find

the 3-6 load match to be

excellent for any kind of speaker ever made, as long as 25W was

enough power required.

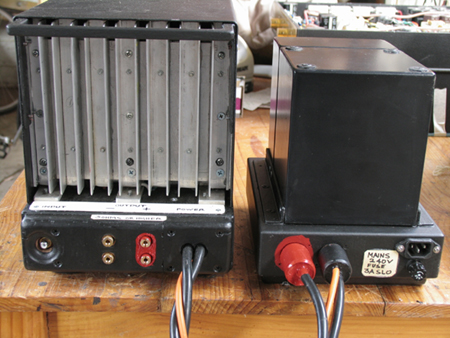

Photo 6.

Here is the under chassis view of each power supply with its

bottom cover removed.

There is a small 5VA auxiliary mains transformer, top LHS. This

supplies 12Vdc power to the

active protection and dc turn on/off circuit. The power

transformer has a board on the RHS

with 48 terminals for taps and ends of windings.

The range of voltages available allow for the use of many

different output tubes and

configurations in future if 845 become scarce or unavailable.

Suitable alternative tubes

are 4 x KT90 in parallel SE with 25% CFB, using the same output

transformer but with

a different winding arrangement on the primary.

Or two x 13E1 can be used. So if ever there are no 845, the amps

can be altered by a

an extremely well skilled tube technician, and sonic purity and

great sound can be maintained

without compromise.

Instead of recycling the amps at the scrap metal dealer, if all

the transformers remain intact

the amps could be re-built into something else, and even a six

pack of EL34, 6L6GC, 5881

could be used.

It is 2016 as I edit this. I definitely will never again be the

available and highly skilled

tradesmen - too many health issues.

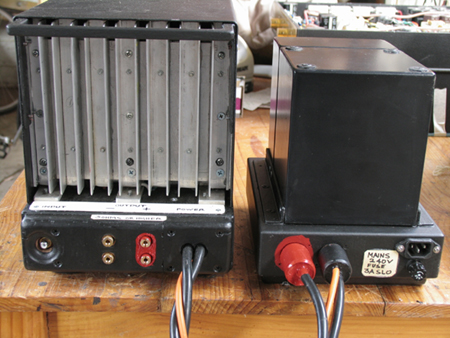

Photo 7.

This workshop picture shows the rear of an audio chassis (left)

beside its power supply (right).

It would be difficult to make a mistake with the umbilical cable

plugs because one is painted

bright red, and so is its socket. When a very absent minded

audiophile inserts both plugs in

reversed and wrong sockets, the amp cannot be turned on and no

damage is sustained when

he turns it on. The choice of pin numbers used for the plugs were

chosen to avoid such an

event, and to keep plug pins with 600Vdc potential difference well

separated.

On the amp chassis there is provision for bi-wiring or having two

speakers into the 4mm bind

posts which are glued into a plywood block to protect them from

breakage, and to ensure

that connections to speakers are only possible with leads that

have 4mm banana plugs.

In other words, the binding posts function as recessed 4mm banana

plug sockets.

Normal binding posts which rely on a wire poked through a hole in

the post and then with a

knob turned tight are an unreliable connection because they

inevitably become loose and

intermittent, and few high-end cables can be used this way. Most

hi-end cables have gold

plated 4mm banana plugs. Way back in 1952, Quad thought the same

way in about 1952

with their Quad-II amps, ( they sold over 100,000 ).

The only problem with 4mm banana plugs is the risk that someone

yanks cable or treads on

cable entry with amps in the floor, and thus breaks off the plug

end, which remains lodged in

the socket. I once did this on a speaker terminal. I used a 1mm

drill to put a hole in plug end

and then used a wire to haul out the plug end. This is highly

skilled work, and I know of

nobody else who capable and who would not leave a messed up

socket.

People who build new amps or speakers should make sure the banana

sockets are mounted

in a small removable panel which is easily unscrewed to allow a

inside access to the 4mm

bore to allow a plug end to be pushed out. I could not find any

such suitable sockets.

The ideal banana socket has not become available anywhere yet.

Input socket is a Cardas RCA input for a single ended input only,

shown recessed on the left.

On the amp rear side to the right, the umbilical cables emerge and

are soldered into the amp to

avoid connection confusion, and the problem of having too many

plug and socket connections.

Cable length is 1.5metres, so the power supplies may sit on the

floor, out of sight, out of mind,

and away from any other gear, while the audio chassis may be on a

bench 900mm high to allow

easy access to the on-off switch, and to keep an eye on the tubes.

The rocker type on-off switch is recessed to avoid damage, and it

switches low voltage 12Vdc.

The actual mains switching is done with relays within the power

supply. Thus 240V mains

wiring is not brought into the audio amp chassis and so there no

diode switching noise spikes

or hums from where the on-off switch is so closely situated to the

audio input circuits.

Schematics.

I have published all my schematics and all amp details for free. I

am not afraid of anyone

stealing or copying anything I have done. But nobody is going to

copy what I have done and

make a profit because these amps will have a cost of production

far in excess of most cheap

nasty toy like amplifiers which one can see advertised around the

Internet.

The few other manufacturers who supply similar power levels of

Single Ended triodes dare not

publish the full details of their amps lest the secrets about

their shortcomings become obvious

to the hordes of people who would publish criticisms and reduce

sales and profits.

Many manufacturers do not want you to know how they managed to get

the cost of production

to down to a very tiny fraction of what they want you to pay.

Nobody could faithfully copy my designs and be able to make a

profit without employing an

arsole to remove the quality to cheapen the cost of production -

thus stealing and ruining

your music, and lessening the amp reliability, so it barely

reaches a typical 90 day warranty

period before the amp troubles begin. I know it happens; I

repaired piles of overpriced junk.

I have never obtained a favorable review from magazines such as

Stereophile after paying the

huge sums. In 2016, I wonder how much relevance Stereophile has

now; I would imagine it

has been severely undermined by the chatter on the Internet.

Nobody really knows who makes

a good amp now - unless proven otherwise - by extensive

revelations of all details, like you see

here.

But most ppl buying hi-end audio do not understand a word I type.

So for them, buying hi-fi

gear is a gamble. Maybe it sounds OK, maybe it lasts, but whatever

happens, they can

buy another solution later if it does not work out. I've known

audiophiles to become tired of

what they bought, and need to replace everything yearly - they

hunt continuously for the

ultimate, always conning themselves they are going to get

something slightly better because

it really is more "ultimate" than the last six purchases. There is

a lot of complex psychology

going on in minds of those who have the money to consume hi-fi

gear with relentless passion.

I am not much surprised by their appalling levels of musical

appreciation. But part of being

human is to consume, and to consume at great expense, and to

excess, and there's never

goods and services and never enough dough to get it all, and

there's never any serious

attention given to frugality, which is hugely

boring.

Warning. There are

high voltage potential differences of up to 2,000V

within each

amplifier when operational.

Only trained and experienced technicians should

attempt to examine the working

circuits or build the circuits shown in the

schematics.

SHEET 1. SE55 input and driver stages.

Input signals enter the input V1 6CG7 with both halves paralleled.

There is a high pass CR

input filter with C1-R1 to give a pole at 5Hz. This keeps out dc

in sources and extremely low

frequency signals. The MJE350 transistor might seem to be quite

out of place in a tube circuit,

but it acts as a passive component which supplies V1 anodes with a

non changing current or

what is called a constant current source, CCS.

The CCS acts in a manner identical to an equivalent resistance of

several megohms to an

imaginary supply voltage of thousands of volts. Such a resistance

and supply are utterly

impractical, and not needed. It would have been possible to use a

pentode to perform the

same function as the MJE350, but in this case the MJE performs

better than any tube.

Because the effective real dynamic collector resistance is so

high, it cannot impart any sonic

signature in the signal path, apart from allowing V1 to operate

with less THD than if it had a

"normal" resistance between the B+and anode.

Best sound with triodes is obtained when the least change of anode

current occurs.

So with the MJE350, V1 anode load is effectively the following

capacitor coupled biasing

resistance R11, 180k. The Ra of V1 is about 5k0, and RLa is 36

times greater than Ra, and

when triodes are loaded with RLa > 20Ra, they give the best

sound, and the lowest possible

distortion measurements. If you were to replace the CCS with a

simple resistance of about 39k,

THD/IMD would increase 3 times. The THD of V1 is mainly all 2H,

but it will add to that of the

output stage because both V1 and output stages have the same phase

of the 2H, so to

minimize overall THD, the CCS transistor helps to lower overall

distortion. The high RLa

value of V1 maximizes its voltage gain, which cannot exceed the µ

of the triode.

6CG7 has same electronic parameters of 6SN7, with µ = 20, Ra =

10k, gm = 2mA/V. Full

explanations about mysterious inner workings of a triode may be

found at my pages

beginning at basic-tube-1.html

Any brand of 6CG7 may used. My favorites were once Telefunken or

Siemans NOS made in

Germany. I've never known anyone who can tell the difference

between the German 6CG7 and

NOS versions made in Australia by AWV before 1965. Genuine NOS

German 6CG7 are hard to

find and ruinously expensive. The expense is because they have

become rare, and not only

because they have a good sound reputation.

I suggest the Australian made AWV are very "fine wines" indeed,

and those who insist the

German triodes are better might do because they have paid so much.

In a blind A-B comparison

they might be surprised.

For greater input sensitivity, 6922/6DJ8 could be used for V1. One

would have to use 2k7 R4 grid

resistors at each grid because the 6DJ8/6922 does tend to

oscillate at around 200MHz if you

parallel the two halves without using two separate series grid R

"stoppers". The cathode biasing

resistor, R5, would need to be reduced in value until Ea measured

about +120Vdc.

The 6CG7 is an evolution of the famous octal based 6SN7. Oz made

samples often used exactly

the same anode, grid and cathode structures but just mounted

slightly closer, and a slightly lower

anode Pda rating given for the smaller 9 pin size. There was often

a screen also fitted between

each anode taken to pin 9 and 0V. The 6CG7 technical character is

identical to 6SN7 and it

ensures the audio signal is amplified very linearly, while

maintaining excellent musicality, micro

detail and warmth, transparency etc that one enjoys with the best

tubes when set as I show.

German 6CG7 and some Japanese 6CG7 were made with smaller anodes

than Australian

made 6CG7 or 6SN7, and some had slightly higher µ 21, or 22. But

anything labelled 6CG7

( or 6FQ7 ) will function well in a circuit designed for 6CG7.

8dB of global NFB is applied from the output transformer through

R3&C2 to the top of R6.

C6, C7, R8, and R11 form a LF gain stepping network to optimize

the LF stability and fidelity.

V2,3&4 are triode connected EL84, each with individual cathode

biasing. Any brand of EL84

may be used, and you could have 3 different brands together if

need be because they each

have their own cathode biasing network. I've fitted Sovtek which

sound well, and mixing up

brands or using 3 x NOS EL84 may or may not make a change.

Three EL84 are used to produce what becomes ONE super triode with

Ra = 700r, µ = 20

and gm = 28.6mA/V. As shown, it makes can easily make a maximum of

164Vrms of signal

Vac with less than 2% THD, and with good gain, and wide

bandwidth.

The use of L1 60H choke plus 7k0 to supply Ia = 36mAdc to the 3 x

EL84 provides a high

ac impedance anode supply load which dissipates an extremely small

amount of ac power,

so hence the excellent linearity, because like V1, RLa is many

times Ra, and RLa approaches

a CCS. L1 has XL = 18k at 50Hz, and at 1kHz XL > 200k. The 7k0

isolates the shunt C and

shunt L of choke, so minimum RLa for EL84 is 7k0. I've always

found the L + R method of

supplying Idc to driver stage anodes in SE and PP amps has given

the best sounding

dynamics, ie, better hi-fi. The capacitor coupled load for EL84 is

the biasing R for following

845, R28&R29 of 23.5k. The use of high Z dc carrying RLa

allows the following biasing R to

be low, to more effectively keep output tubes at the wanted bias

Vdc.

At 50Hz, the EL84 triode RLa = 20k of L1+7k0, plus 23k5 in

parallel for a total of about 16k0.

RLa > 23 Ra. But above 100Hz, RLa = 28 Ra. This ensures minimal

THD&IMD and maximum

fidelity.

There is shunt regulation for V1 anode supply using zener diodes. This assists LF stability.

Any noise in the zeners is filtered by R21 and C9. The CCS MJE350

in series with low Ra

of V1 forms an R divider to prevent any rail noise entering V1

anode circuit.

SHEET 2. Output stage 2 x 845.

Sheet 2 shows each 845 is set up in conditions as follows :-

Ea = +1,060Vdc, Ia = 70mA,

cathode bias voltage = 150Vdc, RLa per tube = 12k0, and so for

both 845, the OPT load is 6k0.

The maximum drive voltage to 845 grids for clipping is up to

approximately 110Vrms containing

1.4% 2H from the driver stage. The driver stage anodes applies the

drive voltage to the network

of C16,17,18 and R23, 24, 25, 28. This network transfers the

signal safely from the EL84 anodes

at +310Vdc to the 845 grids at -600Vdc.

Coupling caps are 2.2uF each and each rated at 1,000Vdc and the LF

pole is at 9Hz.

The 845 anode current is supplied from two rails, one at +600Vdc,

and the other at -624Vdc.

This unusual arrangement reduces the likelihood of arcing within

the OPT between anode

windings and earth potential secondary windings. The filtering of

the two rails is by C-LR-C-R-C

set up to give a damped LF pole. Many tests were done to ensure

the continual mains voltage

level changes and LF switching noise caused by other users

connected to the mains supply

does not create LF resonance signal which then appears between

grid and cathode of the

output tubes, and therefore does not appear in the output in

excess of 0.5mV, even if mains

noise level change is very bad. The overall noise

performance despite the twin rail use is

extremely good. Despite so little global NFB these amps were the

quietest tube amps I have

ever built.

Two supplies of 10Vdc are applied to 845 cathodes xx and yy so

that rectifier ripple Vac > 20mV

and is balanced by R30&31, 32&33.

SHEET 3. Cathode heating with dc for all tubes.

Sheet 3 shows the three simple heater dc supplies used for ALL

tubes within the amp.

The L3, L4 chokes used in the choke input dc supplies for the 845

cathodes are

potted and do not cause any magnetic interference in the potted

OPT on the same chassis.

L2 is a solenoid type of choke in a CLC filter, so the Vac across

the choke is tiny, and thus

its change in magnetic field is negligible, so potting was not

needed.

SHEET 4. Main power supply for 1 channel.

Sheet 4 shows the main power supply chassis has all the above

within to generate the

positive and negative B+ and B- Vdc rails for the 845 and other

tubes. There is also a stand

alone auxiliary +12Vdc rail to supply power for the on-off Relay 1

and for protection circuits.

The use of low Vdc rail for switching mains avoids having any

mains wiring within the audio

chassis. And if any umbilical cable is not plugged in correctly,

the amp cannot be turned on.

Power for DC heating all cathodes has Vac transferred from PT via

umbilical cables and

rectifying Vac is cone on the audio chassis. This avoids high

current DC power transfer by

cables. The noise of diode rectifiers operating to give low Vdc

with low noise does not increase

amp noise. And there was more available chassis space on amp

chassis, and not enough on

PSU chassis. See notes below sheet 6 about power transformer and

iron core component

replacement.

A large number of rail voltage arrangements are possible.

FUSES.

Caution!

The amp must be turned off and mains cables removed from wall

socket before

change of any fuse. Wait 10 minutes before changing any fuse

!!!!!!!!!!!!!!!!!!!!!!!!!!

Fuses or fuse wire links for all windings are as follows:-

F1, Mains input, for 220V,

230V, 240V, 3A slow blow, type 3AG, and accessible at rear of

PSU by owner. For 100V, 110V, 120V operation, mains fuse is 6A

slow blow type 3AG.

All fuses below may only be replaced by a technically trained

person.

F2, F3, F4. Three fuse wire

links rated for 10A soldered into the underside of the psu

chassis and covered with black polyester sleeving for 2 x 845 ac

cathode heater windings

and one other cathode heater winding for 3 x EL84, and 1 x 6CG7.

F5, F6. Two x

3A slow blow, 3AG, soldered into place under psu chassis for the

two main

HT rails of +660Vdc and -640Vdc, derived from voltage doubler

rectifiers.

R58 Provides some protection for the auxiliary small power

transformer under the psu chassis.

This 1W resistor will burn out if the auxiliary transformer is

shorted.

845 Anode fuses, There are two 0.5A slow blow 3AG fuses

soldered between the

bottom of R36 and each 845 anode in case the anode current exceeds

0.6Adc.

SHEET 5. Active protection against excessive Idc in 845.

Sheet 5 shows active protection against lounge-room disasters

including audio silence, clouds

of smoke, and a terrible toxic smell. Tubes don't last forever,

and can sometimes fail randomly

before their expected lifetime.

Often such failures are provoked by a careless owner connecting a

faulty speaker, or allowing

speaker cables to be shorted. In the unavoidable and inevitable

eventual malfunction of one

or more 845 in what is called a "bias failure" event, you want the

amp to TURN OFF as soon

as the tube overheats. The tube may be OK, but there may be some

other circuit fault.

845 are expensive, so they need protection.

I have had to repair very many "good" hi-end brand amplifiers that

gave a lot of trouble due to

poor design, or through mishap caused by owners, or malfunctioning

speakers etc, etc, etc.

Often I have had to repair amps where the fuses were the last

things to blow. On some amps

there was evidence of a small fire which damaged parts of wiring

and circuit boards.

To avoid smoke in the listening lounge room, and collateral damage

to other parts within the amp,

most amp makers do fit a couple of fuses, but they are often

almost useless.

They don't always blow when one wants them to, and owners are

notorious for replacing them

with something convenient like aluminium foil from the kitchen or

using a 2A fuse instead of

0.2A which encourages a faulty amp to burn the house down.

Active protection is needed to automatically stop the smoke and

damage and to tell an owner

when something is wrong, and if possible to shut down the amp and

prevent fuses blowing.

Nevertheless, I have a fair number of fuses fitted in these amps

and apart from the mains fuse

they are all soldered into place because fuse holders are

notorious for not holding a fuse firmly

and becoming loose over time, and thus becoming intermittent

especially with dc flow.

Fitting new soldered-in fuses is a painful exercise requiring a

tech with a soldering iron.

The most likely problem in any tube power amp is the sudden or

gradual unwanted increase in

the idling dc current flow in each output tube. This current is

usually called the anode bias current,

and it is controlled by the voltage between the grid and cathode.

But a tube can change its

character as it ages or during some trauma such as caused by a

shorted speaker cable, and

despite the biasing voltage Vg-k, the bias current may increase to

many times the idle value,

with dire results if not dealt with ASAP, within seconds.

The above simple circuitry will shut down the amp in 90% of bias

failure or tube failure cases,

and if the failure was caused by some temporary fault, it may be

easily reset to go again simply

by switching off, then on again as explained in the text in the

schematic above.

Under normal operation, the 845 anode current is around 70mAdc at

idle. This generates 150V

across cathode R34&R35. Should the anode current ever rise to

about 102mAdc, there will be a

cathode bias voltage of 225Vdc, which means the Pda will have

risen to about 100W, and although

this is the maximum rated Pda for 845, its plain wrong in these

amps and due to a fault condition.

So to give the fault condition it only takes an Ia increase of

32mAdc, or 45%, and you cannot rely

on fuses to blow with such a small amount of current change, so

active protection is the only reliable

way to prevent Ia rising to perhaps 400mAdc in this amp. 400mAdc

would damage the cathode

bias resistors, and perhaps the OPT primary winding if the

condition lingered for too long, and I

have seen this happen in many amps brought to me for repair.

The protection circuits have utterly no effect on the sound.

SHEET 6. Power transformer details.

Sheet 6.

The power transformer does not run very hot because the turns per

volt ratio gives a B-max of

less than 0.9 Tesla, and wire sizes are generous and rated for no

more than 3A per sq.mm of

copper wire section area. The transformer is neatly layer wound

with layered construction shown

in the drawn section through the winding bobbin.

I gave a two year warranty on amp transformers. But if one were to

fail, and I was not around in

future then there are no standard easily available replacements

for any iron cored wound

components in these amplifiers from any known commercial

transformer winder.

All are custom wound and may have to be ordered as a special order

from perhaps Sowter

Transformers located in the UK. Sowter would be the only

transformer maker I know who could

produce a power transformer to do fairly close to what is done by

my originals. But I doubt they

would like to include the the many taps for alternative tube

usage.

I hate to think what the cost of a replacement PT could be from

Sowter.

Most other commercial transformer winders HATE TAPS anywhere; they

just cannot cope with

the levels of complexity and thought I put into all my work.

If one PT were to fail, it would be possible to build two power

supplies on ONE new chassis using

a larger single PT rated at 1.2KVA, and re-use many parts you see

here. This sounds like a huge

amount of work, and it sure is, but it means the single

transformer would have the same core

lamination tongue size of 51mm, but have a GOSS stack height of

100mm instead of the 72mm

now used. Wire sizes would be thicker, but fewer turns per volt

are used, and it’s no more difficult

to wind than winding a pair of PT with cores now rated at 650W for

cool running.

An alternative is to rebuild the power supply on a new chassis to

allow the use of multiple power

transformers which may need to be sourced from Hammond Engineering

in Canada. In 2016,

I am not sure if there is a reliable supplier of Hammond products

in Australia. The Oz company

evatco.com.au changed hands 2 years ago and I don't hear any good

reports of how it now deals

with mail orders. So if you need a new PT for these kind of amps,

you would have to consider

completely re-designing and re building one big PSU to cater for

both channels. Experts who

specialize in such work have all retired or died, and I've

retired, and will die soon.

I sold the pair of 845 SE55 to a customer in Australia in 2008. I

retired from the amp trade in

2012. Its now 2016, and my customer has not had the amps ever

serviced here so I guess he has

not ever had any need to replace any transformers or other parts

requiring my past expertise.

The OPTs and PTs can be removed from chassis, terminal boards

removed, and sealing layer

of resin and sand concrete seal removed with chisel and hammer.

The remaining loose dry sand

surrounding the transformer can be drained out. The transformer

should be able to be removed

from its pot and thus the pot can be re-used.

To dismantle the wound transformer all bolted angles and bolts are

all removed. The grain

oriented silicon steel core can be salvaged by heating the

transformer in a small wood fire to

burn off plastics and varnish. When cool, the burnt wire is cut

away for re-cycling, and laminations

should all fall easily apart and will be ready for re-use. The

slow heating and slow cooling will NOT

affect the core magnetic properties. A new transformer is then

wound using a new plastic bobbin to

suit a 70mm stack of 51mm tongue laminations so that it will fit

inside the pot. The newly wound

transformer must be varnished while being wound or after with a

soak and bake method.

A new terminal board is made and fitted.

After testing the new transformer it is re-assembled back into its

pot and clean dry sand used

to fill the pot except for the last 15mm. The sand must be

thoroughly vibrated and settled.

Spray-can varnish is applied to the sand surface and next day the

top 15mm of fill is with a 50-50

mix of epoxy (fibreglassing) resin and sand. This seals the pot

and prevents dry sand running out.

The spray varnish prevents liquid resin soaking into dry sand

below. The completed tranny is

re-installed into the chassis and connected up and tested.

This is what is involved with serious repair to these sort pf

amps. I have done this kind of work on

many amps I serviced.

In 2016, I DO NOT know anyone in Australia with sufficient

competence, knowledge and

patience to do such work on transformers.

The gentleman who made the amps has got old, and is now quite a

bit stuffed up from countless

years of toil to please other ppl plus a number of health

problems.

The power transformers and other wound components such as chokes

and OPT have been

designed to run cool, and all windings have fuses, and active

protection is used against output

tube failure. I believe I have done enough to ensure transformers

will survive a long time.

After winding so many power and output transformers and chokes

between 1994 and 2012, not

one has failed, so I have never needed to repair any of my work.

Much time has been spent on making the iron cored items in these

amps.

SHEET 7. OPT for SE55.

Sheet 7. shows the OPT details which was layer wound and varnished

with Wattyl 7008

polyurethane two pack varnish generously applied to windings as

the transformer was wound.

The completed OPT was potted in a zinc plated sheet steel pot and

filled around with dry sand

well compacted with a finishing layer of epoxy-sand concrete.

The output transformer is more difficult to wind than the power

transformer because of the

high number of layer wound turns around a large core with fine

wire only 0.52mm dia.

There is no known ready made replacement type available from any

manufacturer such as

Hammond Engineering. Perhaps Sowter in UK may wind a new OPT, do

not expect them to

adhere to my recipe for an SE OPT for 6k0 : 4.0r or 6.25r. They

just choose something "close"

from their list of hundreds of OPTs wound after WW2. I did once

pursue Brian Sowter to

obtain a quote to wind a replacement OPT for Quad-II amps which

would be much better than

the original, and fit on the original chassis. He would NOT wind

it just how I had it detailed.

When questioned just how he would wind it, so I could compare my

design with his, to see if

better or worse, he refused to ever tell me. His designs were his

trade secrets, and were not

ever to be given to anyone else. And certainly never to some

up-start nobody from Australia

who knew more about how OPTs functioned than he did. This became

obvious during the

emails. The costs were huge to have him do anything.

So, this is why I just could not ever deal with anyone who could

not prove they knew all about

what they were selling, and who could not design any OPT from

scratch without reliance on any

previous records. So many ppl who say they are experts are not

experts.

Ian Sowter, Brian's father, WAS a huge expert and much advanced

the knowledge of audio

transformers well before WW2. Brian probably had so much to occupy

himself with in daily

running of the company that he may have escaped having to ever

proove he knew as much as

his dad, and could design an OPT - until I came along to ask him

questions he could not answer

to my satisfaction.

The dynamic anode resistance Ra of the two 845 in parallel is 1k1

and when this Ra is in parallel

with an anode load of 6,000 ohms, the source resistance = 930r

shunting the primary inductance

of 40H with 150mAdc present. The -3dB response drop at LF and low

levels below Fsat and due

to primary shunting inductance occurs at 4Hz. At 50W output level

the onset of core saturation

occurs just under 20Hz. And at 12.5W, with Va = 1/2 that for 50W,

Fsat = 10Hz.

The RLa of 6k0 = XLp at 24Hz. So when testing the amps with 6k0

anode RLa, the THD at

50W level rapidly increases below 24Hz because the load has become

partly reactive with Lp in

parallel with RLa to give total load impedance = 4.24k. But at

12.5W the THD increase at

LF is very much less.

At 50W, the HF -3dB point is above 30kHz, all with zero global

NFB. Some of the slight sag

in HF is due to the stability network of R37&C23 beginning to

load the amp above 50kHz.

Shunt Capacitance from the primary anode terminal No1 to the

secondary is less than 3,000pF.

Leakage Inductance has slightly less attenuation effect than the

shunt capacitance, and

the resonance between leakage L and Shunt C is above 30kHz.

Primary winding resistance Rwp = 95r for 2,760 P turns, using

0.45mm dia copper wire, about

0.52mm oa dia with enamel. Rwp loss% = 1.56% with RLa = 6k0.

Secondary winding resistance = 0.124r for 5 x 72 turn secs in

parallel, 0.9mm Cu dia wire.

Rws loss% = 3.0% with Sec RL = 4r0.

Sec winding resistance referred to primary = 182r so total Rw =

95r + 182r = 277r.

Total Rw P + S loss% = 100% x 277 / 6,277 = 4.44% with RLa = 6k0.

This result should be equal

to 1.55% + 3.0%, 4.55%, but is obviously not, but the referencing

of Rws to primary assumes

some slight difference in equivalent L+R schematic. The referring

to primary of secondary Rws

is still accurate enough to use. The higher figure of 4.55% is

very good because many SE OPTs

measure with much higher winding losses with 7% to 10% being

common.

Where a speaker is say 6r0, and connected to OPT set for 4r0,

total winding losses reduce to 3.0%.

LOAD MATCHES AVAILABLE.

5 x 72 turn parallel secs give TR = 2760t : 72t = 38.333 :1. ZR =

1,469 : 1. A sec load of 4r0

gives RLa = 5.877k plus Rw 277r = total anode load = 6.154k. Near

enough to 6k0.

All speaker loads above nominal 3r0 Z rating may be used.

4 x 90 turn parallel secs give TR = 30.666. ZR = 940 : 1 so for

sec RL = 6.25r, anode loading

is the same as for 4r0.

All speaker loads above 5r0 may be used.

The current density for all sec winding wire is the same for

5//72r or 4//90t.

The third option is to use 4//72t in series with 2//36t for Ns =

108t.

OPT TR = 25.555 : 1. ZR = 653 : 1, so for same RLa load as before,

Sec RL = 9r0.

This allows all speaker loads above 7r0. The total winding losses

will increase slightly

by maybe 1%, and HF pole may slightly reduce, and the hi-fi

experience will not change.

All speakers including ESL types by Quad such as the ESL57, ESL

63, 989, 2805 should be

tried with the 4r0 setting before committing to the trouble of

changing the setting to a higher one.

Many older high impedance speakers of say 16r0 are much more

sensitive than more modern

types, and therefore require a similar amount of signal voltage as

a modern 4r0 speaker.

The amp current needed for 16r0 is 1/4 of than for 4r0, the RLa

becomes 24k0, and max Po

will be only 15W, but DF and THD are both more than halved, and

sound is unsurpassable.

Most people will never use more peak power above 10W. Average

power is well below this,

often only 0.25W per channel. Because the amp measures so well at

55W, at an average power

of 1W the distortion is well below audibility.

SHEET 8. Choke details SE55.

Sheet 8.

Six chokes per channel are used for filtering and to prevent the

heat losses using alternative

methods of filtering or active regulation. No solid state chip

regulators are used because they become

unreliable when used in circuits with such high voltages lurking

about. There are a few simple zener

diodes for basic shunt regulation, but used so they are under no

heat stress. The main positive and

negative voltage rails of over +600V and below -600V have a

C-LR-C-R-C type of filter. Each C is

formed with 2 x 470uF in series to make 235uF, and total C per

rail = 705uF. There is a resonance

between the 4H choke and following 235uF at 5.2Hz. The added 100r

in series with L reduces the

noise peak at 5.2Hz. The following additional 100r plus 235uF act

to damp the peak in the resonance,

thus making each voltage rail less liable to vary at LF below 10Hz

due to the unavoidable mains

voltage level changes that occur continuously, and typically of

+/- 20mV to +/-200mV.

I have found the steady average value of mains voltage can be from

235Vac on a cold winter evening

to +255Vac on days with little mains load, with 247Vac being most

common here in Canberra.

Many high end brand amps have been designed to run in the USA with

a nominal 110Vrms mains or

220Vrms. Many such amps have fixed bias and tubes run

unnecessarily hot even with the correct

mains voltage present. But here the mains voltage is often 250Vac,

and with fixed bias these amps

often overheat badly when tube Pda rises close to or above the

rated maximum Pda. Jolida and ARC

amps suffer in this manner badly, and need to have alterations

made to their PSU to prevent the B+

from exceeding the capacitor voltage rating and to stop the tubes

exceeding their Pda levels.

Many owners have thanked me for the efforts I have made in this

regard. But in my amps, there are

tapped windings to allow for worst case voltage variations.

The SE55 work just fine where average mains = 245Vac, but will

work fine with mains between

220Vac and 255Vac. The maximum output power will vary between +5%

for higher Mains Vac and

-10% for lower Vac, so between 58W and 52W. It is quite "enough"

power.

SHEET 9. Resistor layout on heatsink.

Sheet 9 shows the arrangement of resistors used within the

aluminium heatsink at the rear end

of the amp chassis. Cheap ceramic bodied wire wound types are used

with their dissipated power

being well below the rating for the resistance chosen. These are

readily and cheaply available

from many suppliers. A total of about 50W is dissipated in the

resistors shown with normal

operation. To keep them all cool and thus more reliable, the

heatsink was built up to enclose the

resistors behind a removable cover fitted with many fins and which

springs tightly against the

enclosed resistors.

Resistors are glued to the 3mm thick aluminium heatsink fixed

plate with Selleys 401 engineering

grade silicone with a temperature rating of 200C. The screwed

cover can be removed by

removing the 9 x 4mm metric machine screws. White heatsink paste

is used between resistors

and the cover. While it is possible than resistors might fail, my

experience tells me it is not likely

that they will fail, unless the current flow is 10 times more than

normal. Wire wound resistors usually

fail by fusing open, and they may be prized off the heatsink with

a chisel, and a new one fitted.

The standard size for 5W and 10W white ceramic boxed R have

section size 10mm x 10mm so

will fit the same space for them.

It is a messy job to replace any resistors, and a tech needs to

know what he is doing, but at least

the resistors are easily accessible once exposed to view. While it

may have been wiser to use

much more expensive aluminium bodied resistors each screwed to a

heatsink, there was no need,

and the method used is entirely adequate, and any fused resistors

are cheap to source and easy

easy to replace.

SHEET 10. Umbilical cable details.

Sheet 10 shows the layout for rugged cables used to get power from

the power supplies to the amp

chassis. When the amp chassis are examined with a copy of the

above, just exactly how everything

is set up becomes less confusing. The octal plugs at the ends of

cables are permanently connected.

All wires are soldered into the hollow pins of the plugs. There is

no access to the wire ends leading

into the hollow pins of the plugs. If a pin is broken off a plug,

the whole plug is made useless.

The only solution is to cut the plug off, and rewire a new octal

plug onto the lead as shown above.

A cheap type of octal plug from RS components could be used to

make a new plug.

The original plugs were made using only the bottom base from an 8

pin octal tube. This had the sides

ground off so the base fits neatly inside a 30mm long piece of PVC

electrical wiring conduit tubing with

about 25mm internal dia.

The central keying spigot of the plug has a 4mm threaded rod

inserted to reinforce the spigot which

otherwise will all too easily be broken off accidentally by a

careless owner, leaving no way to correctly

locate the plug into the socket at the power supply, and therefore

promoting many bad tempered

experiences while trying to make the amplifiers work. Both plugs

MUST be plugged in correctly for

the amp to be able to be turned on.

There are some inbuilt safety features of the umbilical cables.

While plugged in there is little danger. The danger from a shock

is no worse than any normal 240V

wall socket plug used for many other household appliances. It is

impossible to turn on the amps with

only one octal plug plugged in, or with plugs reversed, i.e, and

red into black socket, black into red

socket.

However, if somebody were to wrench one of the power supply cables

from the power supply while

the amps are turned on, the amps will turn off immediately. If any

person were to immediately grab

the pins of the plugs after removing them, then they would be

connected to the live stored voltages

within capacitors in the amplifier chassis. Diodes have been

placed to prevent the flow of current

from these capacitors, see D1, D2, sheet 2, thus preventing a

shock. The 845 cathode heater

supplies are biased at the cathode voltage of -450V but at turn

off there is a relay to reduce this

voltage to less than 40V within less than 0.5 seconds, so it would

be very unlikely to experience

any kind of accidental shock unless one tried desperately to do

so.

It would be unwise to allow a pet dog to chew on cables. Most

animals will get a surly warning from

Unkel Sparks as they chew, and and learn to leave them alone. The

cabling used is particularly rugged

industrial grade cabling with thicker PVC insulation than used for

high power 240Vac rated cables.

Indeed the cabling is normally used for 415Vac 3 phase high power

supplied to industrial electric

motors. Peak Vac with back emf in such cables could be 1,000V. The

highest voltages are carried

in the two thick black cables while very low voltages are carried

by the orange cable.

For all things you cherish, my practiced care was my best

insurance. It was impossible easily build

such amplifiers to be fully child safe. Little hands will reach to

touch anything. However, the tube

heat will cause pain before a burn is sustained, and children soon

learn the danger of anything hot.

If there is any doubt, supervise children, if not, make sure the

amps are secured so a bench, and

additional mesh screens made and fixed to prevent child access or

amp movement. When I was

a child, I don't recall I cause grief to my parents by upsetting

the many dangerous things in our

lounge-room. When I did eventually become curious about hot vacuum

tubes in open-backed

radio sets, I was about 15 years old, not 15 months old.

Place power supplies on the floor behind the amps. Cables and

speakers should not pose a risk

of being tripped over by passing traffic. These amps have been

made fairly ruggedly with steel

chassis. All tube amps don't like being dropped, or pulled off a

bench by a trip on a cable.

Metalwork can easily be damaged in falls because of the weight.

Amps should never be moved

while turned on. The umbilical cables should be unplugged, and

coiled up and tied up to the rear

carry handle on the amps. Never ever let cables trail along on the

floor to get under your feet, or

catch on anything.

--------------------------------------------------------------------------------------------------

There was a "Sheet 11" which showed a graph of THD Vs Power output

but this has become

corrupted and I did not have any back up copy.

So what is the THD, Total Harmonic Distortion?

All amplifiers and many transducers add noise and harmonic

products to any signal flow.

If you have a single triode making 10Vrms of 1kHz, the triode may

add 0.1Vrms of 2kHz which is

1% 2H. There may 0.025Vrms of 3H, = 0.25%, and similarly, perhaps

0.025% of 4H.

Many H products are generated, but the 2H will be the largest H

with a triode.The total value of all

harmonics is calculated =

THD = square root ( 2H squared + 3H squared + 4H

squared.........).

For the sample above, THD % = sq.rt ( 1squared + 0.25 squared +

0.25 squared ) = 1.125%.

Where 2H much exceeds all other H, by at least 5 times, as is

typical for a triode at low levels,

we may ignore all high number H and just concentrate on 2H.

All THD is a devil in the music. But every music tone has many H

products. If the levels of these

H are slightly altered by 1%, nobody notices. But where there is a

pure tone, adding 1% of 3H

may be audible. The real horrible work by the THD devil is to

produce Intermodulation Distortion,

IMD.

The THD figure is really a description of the transfer function of

the amp. Let us assume an SE

triode amp makes 5% 2H near clipping with 80Hz. It means that the

tube gm and gain varies for

each 1/2 sine wave. If a second signal tone of 5kHz is introduced

at input, and at 1/4 of the level

of the 80kHz, the amplitude of 5kHz will be varied; it is

amplitude modulated and at amp output

we will find the following H products :-

80Hz, 160Hz, 5kHz, 4.92kHz, 5.08kHz, 10kHz. The 4.62kHz and

5.08kHz are not harmonious

with fundamental tones 80Hz or 5kHz. It is the IMD which is the

devil's work on fidelity.

If the tube amp THD is mainly 2H or 3H and less than 0.5% near

clipping, and declines linearly

with output Vo, then music will not be spoiled. Most music from a

50W amp will be heard using

levels at each speaker < 1W, where Vo = 1/7 of the level at

50W. THD at 1W should be > 0.071%,

and the resulting IMD below audibility. Despite all the figures

for tube amps being worse than

solid state amps, I attended enough audiophile club meetings and

dealt with enough customers

to keep a firm belief that triodes are relevant in 2016.

The whole subject of THD and IMD has been given an enormous amount

of attention by scholars

since about 1920 to about 2010 which was the "analog era". Digital

techniques have largely

taken over all aspects of music recording. So scholars have

stopped talking about distortion it is

old fashioned, and not one young man can demonstrate how clever

and employable he is after

writing in a magazine like Wireless World, which later became

Electronics World.

The number of IMD products between the many frequencies of music

become infinite and audibly

very noticeable where THD > 0.5%.

The standard IMD tests in 1950 used say 80Hz and 5kHz tones in 4:1

vac ratio, and the IMD %

was the amount of amplitude modulation which was measured for 5kHz

and due to larger 80Hz

Vac.

During 1990s, it became fashionable to measure IMD products

generated by two equal amplitude

signals, say 5kHz and 8kHz. The IMD products will be sum and

difference between the two F,

so you should get IMD = 3kHz and 13kHz. The 3kHz is easily

filtered using a BPF filter with Q =50.

The amp is raised to clipping levels and IMD % is 100% x 3kHz Vac

/ ( sum of 5kHz + 8kHz ).

There is no need for IMD testing in tube amps where max THD is

below 0.5%, and as long as

the average level is well below clipping level the sound should be

fine. No amount of technical

assessment explains why listeners hear a difference when Russian

6CG7 are replaced by AWV

6CG7 60 years ago.

For more about THD / IMD measurement, see thd-measurement.html

NOISE. The 845 amps were

among the most silent amps I ever made where no signal is present.

They were quieter than anything mass produced. Without and signal

and with inputs shorted to 0V,

noise could only just be heard if an ear is held tight against a

midrange speaker. I measured noise

less than 0.35mV for both channels.

Maximum power is 55W to 4r0, with Vo = 14.83Vrms. The ratio of

noise : maximum Vo = 42,000 : 1.

Thus official SNR = -92dB, ie, noise is 1/42,000 of the maximum

Vo, un-weighted.

This is remarkable considering there is only 8dB GNFB. Tube noise

and power supply derived

noise remains negligible at high levels of music.

845 SE 55 DISTORTION. THD

at clipping is mainly 2H, with some 3H, 4H and 5H well below the

2H.

The amps will comfortably give huge sound levels into any type of

speaker over 3r0 including ESL.

The measurements here are for OPT set to give 6k0 : 4r0 load.

( This means that with 4r0 speaker, each 845 has RLa load = 12k0.

)

I measured THD = 2% at an "illegal" power output of up to 60W into

4r0 with some class A2

working. But at 50W at the class A1 clipping level, THD = 0.5%.

The first 10W for any load over 3r0 produces less than 0.15%.

The lowest THD at all levels occurs with a 7r0 load. The primary

OPT load becomes 10k5,

with each 845 loaded with 21k0.

The low THD is due to natural second harmonic distortion

cancellation that occurs between

the EL84 driver and output 845 triode amplifier stages. THD

artifacts generated during normal

loud listening never rise above 0.05%. IMD artifacts consist of

those harmonics related to the

second harmonics of fundamental tones. Such "2H" related IMD

harmonic products are the

subjectively "least worst" type of IMD distortions.

If you have 1.414Vrms at the output with 4 ohms, the power level

is 0.5W. If speakers with

average sensitivity produce 89dB SPL for 1W/M, the total of 1W

from both channels combined

gives 89dB SPL. Probably your wife will tell you to turn it down!

She will find average levels of

84dB to be just right.

At 0.5W into 4r0 ohms, THD < 0.05%. This is 0.7mVrms. If

we could listen to that 0.7mV THD

played alone in 89dB/W/M speakers we would find the sound of the

distortion would not be

audible, or about as loud as nervous mouse sneaking across the

floor to get past a sleeping

cat. The IMD will also be negligible.

The subject of THD for SE triodes is dealt with at my page to work

out ideal loading for SE

triodes at loadmatch1-se-triodes.html

See the loadline graphs for SE 845 at bottom of the page.

BANDWIDTH. At ordinary loud levels bandwidth is 5Hz to over

50kHz, which is slightly better

than the amp with no global NFB, as quoted above.

DAMPING FACTOR. Non technical people might think about mops

and buckets of water

when the words "damping factor" are used. Not one amplifier ever

made is perfect, and

whenever a speaker load is connected, the Vac without a load is

seen to reduce.

Amplifiers are like a generator working to provide power for a

carpenter to cut wood.

Each time he cuts wood, the generator Vac falls from say 245Vac to

235Vac. This is tolerable,

and output Vac regulation % = 100% x Vac change / Vac without load

= 100% x 10V / 245V = 4.08%.

We can say that if the generator's internal resistance was 4.08%

of the saw's resistance while

while working.

Consider the 845 SE 55 amp. If it makes 10Vrms without speaker RL,

and you connect 4r0, the

Vo falls to 8.88Vrms, and you have 2.22A in 4r0. The Vac drop at

amp terminals = 1.11Vrms, and

the amp output resistance Ro = 1.11V / 2.22A = 0.5r.

No matter what load above 2r0 connected, we will always find Ro =

0.5r.

The damping factor, DF = speaker RL / amp Ro, and for 4r0,

DF = 4.0 / 0.5 = 8.0.

If the speaker = 5r0, DF = 10.0, and if 10r0, DF = 20.0.

The 845 SE55 was designed to work best with load of 5.6r0. DF =

11, quite OK.

Most dynamic speakers have peaks in Z of maybe 35r at bass F so

the DF would be 70

where RL = 35r. There is no need to ever have a DF better than 10.

In the SE845, the small amount of 8dB of GNFB reduces the Rout

from 0.93r without any

NFB to 0.5r with the NFB.

I have tried the 845 without any GNFB. No change to the sound

quality was heard.

One must be flexible about damping factors, and not be too

obsessive and that isn't easy

for many audiophiles, especially the hard to please majority who

just cannot understand

anything I have said above.

And for more explanations for more things that are inexplicable

such as negative feedback,

please travel to elsewhere in my website to become truly confused

by science.

Negative feedback is a circuit technique used to give a positive

outcome, allowing tubes

to give their best. But audiophiles really cannot stand that one

horrible word "NEGATIVE".

The 845 SE44 depend on a large amount of applied science and

calculations to give the best

sound possible from tubes. I doubt very much that there would be

any change to the sound if

I were to use exotic materials such as 50% nickel in the output

transformer cores, or pure silver

wire. Audio Note in Japan made Ongaku amps with 211 which did have

50% nickel plus 50%

grain oriented silicon steel E&I core laminations, and had

silver enameled winding wire.

All sorts of fancy claims were made about the superior sound

because of the exotic materials

but there has never been any reliable blind AB test between the

Ongaku and the same circuit

with mere copper wire and all Fe-Si GOSS core, and made by the

same man, and honestly

tested and reviewed. Many claimants in the hi-fi industry would

desperately avoid any

exposure to tests which challenge the validity of the claims made.

Two Ongaku amps cost

$140,000 in 1995. I see that anyone spending that sort of money

for a total of 40W of power

has been well and truly conned.

Audiophiles make outrageous claims about sound quality. Some

maintain it is the part quality

or brand that matters most, with tubes, capacitors, resistors,

cables, solder type, all of which

is not the full story which should include the choices of tube

type, circuit used, and measured

distortions and the amount of negative feedback and how it is

applied. Then there is the choice

of input and driver tubes and their technical set up. I've never

witnessed an audiophile changing

his output transformers. There are miles of plain old copper wire

in there. They'll wax lyrical

about pure choke loading to gain stages, but this often achieves

much higher distortion than

when using a simple resistor only, depending on who has made the

choke and the tube type

chosen. At low typical listening levels there can be considerable

iron caused distortion which

resembles the dreaded crossover distortion in SS amps at low

levels. Chokes are only fabulous

as I use them with a series resistance, and where the signal is

high as in the above EL84 driver

circuit and where the Ra of the tube is very low. Solid state CCS

load on the input tube works

better than any choke plus resistance, but is limited to where

signals are low because of the

fragility of solid state where high voltages lurk. Chokes without

the series R as well reduce

the bandwidth and increase phase shift at extremes of F and may

cause instability oscillations

where even a small amount of global NFB is used, which is a reason

why global FB is not

used; the makers don't know how to use it with corrective phase

shift networks.

Without the numbers being naturally very good, no quantity of

exotic minor parts or materials

will make a lemon taste sweet. But if the numbers are really good,

then some slight sonic

gain might be made with choice of tube and capacitor brands.

I find that capacitor brands used in tube amps make little

difference, but do make a difference

in speaker crossovers, and my tip today is that you should only

use polypropylene capacitors

in speakers with high current capacity such as "motor start"

polypropylene caps, and its best

to never use any bi-polar electrolytics. Most makers don't do this

because of cost and size of

poly caps. I only use polypropylene coupling caps in amps, and I

cannot tell any improvement

has occurred if an alternative brand of polypropylene cap is used.

But feel free to experiment, it won't do any harm, if you know

what you are doing.

More pictures.....

Photo 8.

Photo 9.

Back to

poweramps.

Back to index

page.